Need help selecting the right FLEXAMAT? Use our Product Recommender.

Choose the right Flexamat for your site.

Take our Flexamat Quiz to find the right product for your next Project. Take the quiz now.

A double-layered underlayment system, that includes, a 5-Pick Leno Weave and an Aspen curled wood excelsior blanket, Curlex II. This underlayment encourages vegetation growth and is biodegradable. The Standard underlayment is designed for regions and applications where vegetation growth is sustained year-round.

The Leno Weave locks the underlayment fibers under the Concrete Block Mat in extreme flow and wave conditions. The Curlex fibers are specifically designed to promote vegetation establishment. Unlike straw, the Curlex fibers do not float! The fibers have a density value greater than 1.0. Another important difference is the wood fibers are naturally seed free. Additionally, Curlex has a built-in swell factor, where the wood excelsior fibers expand in thickness and interlock to form a strong matrix, while simultaneously retaining moisture to promote ideal growing conditions.

.png)

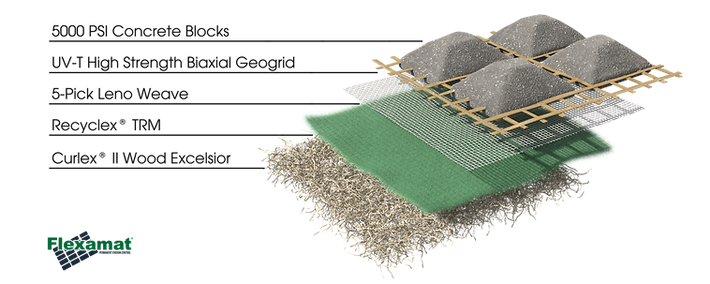

A triple-layered underlayment system, that includes, a Leno Weave, Recyclex TRM, and a base layer of Curlex II Wood Excelsior. This underlayment is used when sparse growth is expected. Examples include semi-arid environments, areas susceptible to drought, areas with poor soils, and/or heavily shaded areas.

The Leno Weave locks the underlayment fibers under the Concrete Block Mat in extreme flow and wave conditions. The recycled fibers in Recyclex provide a permanent layer. Unlike straw and other TRMs, the Recyclex and Curlex fibers do not float! The fibers have a density value greater than 1.0. Another important difference is the wood fibers are naturally seed-free. Additionally, Curlex has a built-in swell factor, where the wood excelsior fibers expand in thickness and interlock to form a strong matrix, while simultaneously retaining moisture to promote ideal growing conditions.

The Concrete Block Mat is manufactured with the concrete blocks cast onto a 10oz. non-woven geotextile underlayment that is adhered to the back of each block.

This backing is used in arid areas, applications where growth is not desired or when the mat is being used as a drivable surface. Flexamat 10NW also used when Flexamat® is installed over plastic liners. The fabric provides a protective barrier between the liner and the concrete blocks. Project requirements determine the fabric used, Flexamat can be manufactured with a wide range of non-woven fabrics.

The concrete blocks of this product have an exposed aggregate exterior. The cement on the exterior of the blocks is washed away during the manufacturing process, leaving the natural aggregate finish for the blocks. This results in naturally appearing blocks that blend in with the native landscape.

Interlocking Geogrid Options

Fornit 30-30-35 polypropylene bi-axial geogrid - used in all Flexamat products unless specifically noted. The bi-axial geogrid has a tensile strength of 2055 lbs and is UV stabilized. This geogrid was selected after years of research and field testing. Polypropylene geogrid is not adversely affected by the high pH environment encountered when embedding the grid within wet concrete. (Polyester yarns degrade when exposed to uncured, wet concrete having a pH of approximately 11.5.)

For applications with high ultraviolet exposure, we developed the UV-T series of Flexamat products. Flexamat UV-T products are manufactured with a 30-30-35 bi-axial geogrid that has an additional high ultra-violet resistant synthetic rubber blend coating that is tan in color (for identification).

A flame-resistant Flexamat was developed for applications that may encounter controlled burns or wildfires. The Flexamat FR series of products are manufactured with a flame-resistant geogrid that is bright yellow in color (for identification).

.png)

The interlocking bi-axial polypropylene geogrid has an additional high ultra-violet resistant synthetic rubber blend coating with a tan color (for identification). This material is used on Flexamat® projects in arid, desert climates where sparse vegetation growth is possible.

It has a triple-layered underlayment system, that includes, a Leno Weave, Recyclex TRM, and a base layer of Curlex II Wood Excelsior.

The Leno Weave locks the underlayment fibers under the Concrete Block Mat in extreme flow and wave conditions. The recycled fibers in Recyclex provide a permanent layer. Unlike straw and other TRMs, the Recyclex and Curlex fibers do not float! The fibers have a density value greater than 1.0. Another important difference is the wood fibers are naturally seed-free. Additionally, Curlex has a built-in swell factor, where the wood excelsior fibers expand in thickness and interlock to form a strong matrix, while simultaneously retaining moisture to promote ideal growing conditions.

.png)

Bi-axial Polypropylene geogrid with a high ultra-violet resistant synthetic rubber blend coating with a tan color (for identification). This material is used on Flexamat® projects in arid, desert climates or areas where vegetation growth is not possible or not desired in applications where the mat will not be infilled.

The Concrete Block Mat is manufactured with the concrete blocks cast onto a 10oz. non-woven geotextile underlayment that is adhered to the back of each block.

Bi-axial Polypropylene geogrid with a high ultra-violet resistant synthetic rubber blend coating with a tan color (for identification). This material is used on Flexamat® projects in arid, desert climates or areas where vegetation growth is not possible or not desired in applications where the mat will not be infilled.

The Curlex Net-Free underlayment contains no netting and is 100% biodegradable. It is manufactured with Great Lakes aspen.

Flame Resistant Geogrid - a bi-axial geogrid with flame-resistant coating. This material is used on Flexamat projects in areas where wildfires or controlled prairie burns are anticipated.